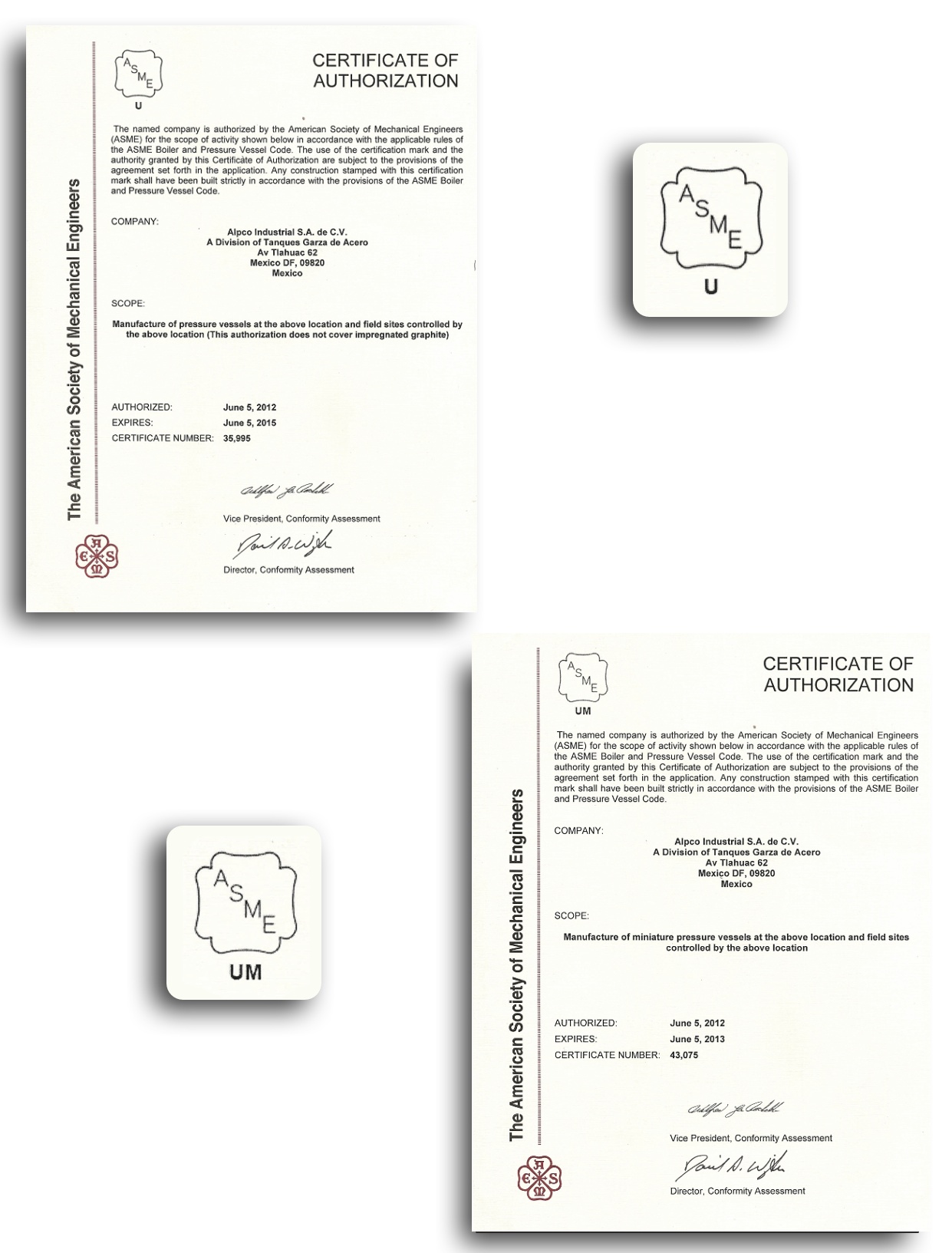

The American Society of Mechanical Engineers

Is a professional organization with the purpose of developing quality standards to govern the manufacturing of pressure vessels.

Engineered Pressure Vessels, Co. is one of the companies in the United States with a Quality Assurance System Certified by ASME, where our commitment with quality is documented in each and every one of the vessels we manufacture.

Why is ASME so important to Engineered Pressure Vessels?

Because to comply with the Rules for Construction of Pressure Vessels of the ASME Boiler and Pressure Vessel Code, we make sure you are getting a safety product at the highest quality.

When you require a Pressure Vessel, be sure to meet 100% the ASME Code, specifying the total compliance with ASME Code Section VIII Division 1, Latest Edition.

By their general nature, Pressure Vessels require expertise to be manufactured; knowledge and expertise are keys to the production of safe and long lasting Pressure Vessels.

Custom tailoring the product to meet your specific needs is very critical, an area at which we excel.

The ASME Code is divided into eleven sections and each of them, deal with particular areas, but there are four sections of the ASME Code we are involved with day by day when we manufacture a Pressure Vessel:

The section VIII Division 1: Establishes the rules for construction of Pressure Vessels.

The Section II: Is divided into four parts: A, B, C and D.

The Part A: Shows all the Ferrous Material Specifications such as Quality, Chemical Composition, Tensile Requirements, etc.

The Part B: Shows the Nonferrous Material Specifications.

The Part C: Shows the Specifications for Welding Rods, Electrodes and Filler Metals.

The Part D: Shows the Properties for Ferrous Materials.

The Section V: Determine the Rules and the procedures for all the Nondestructive Examination: Radiographic, Ultrasonic, Liquid Penetrant, Magnetic Particles and Leak Testing.

The Section IX: Relates to the Welding General Requirements such as Procedure Qualifications, the Qualification of Welders, Welding Operators and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators. Once any ASME Stamped Pressure Vessel is manufactured, it is checked, tested and approved by the ASME Authorized Inspector, who review all the procedures and all the documentation and sign the Data Report Form before to procedure to  Stamp the name plate with the "U" or "UM" symbols, which means that the Pressure Vessel fully comply with the ASME Code rules for construction of Pressure Vessels.

Stamp the name plate with the "U" or "UM" symbols, which means that the Pressure Vessel fully comply with the ASME Code rules for construction of Pressure Vessels.

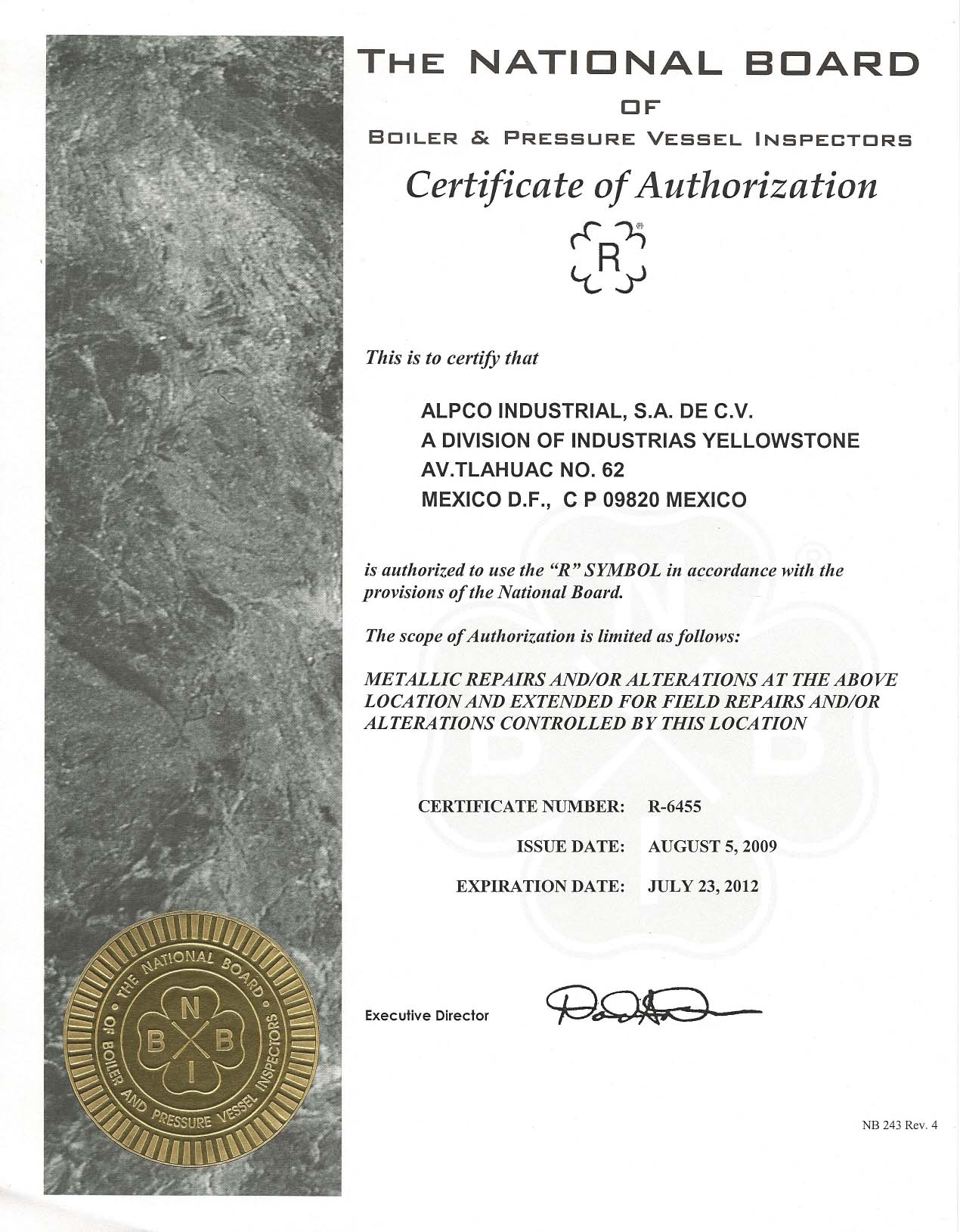

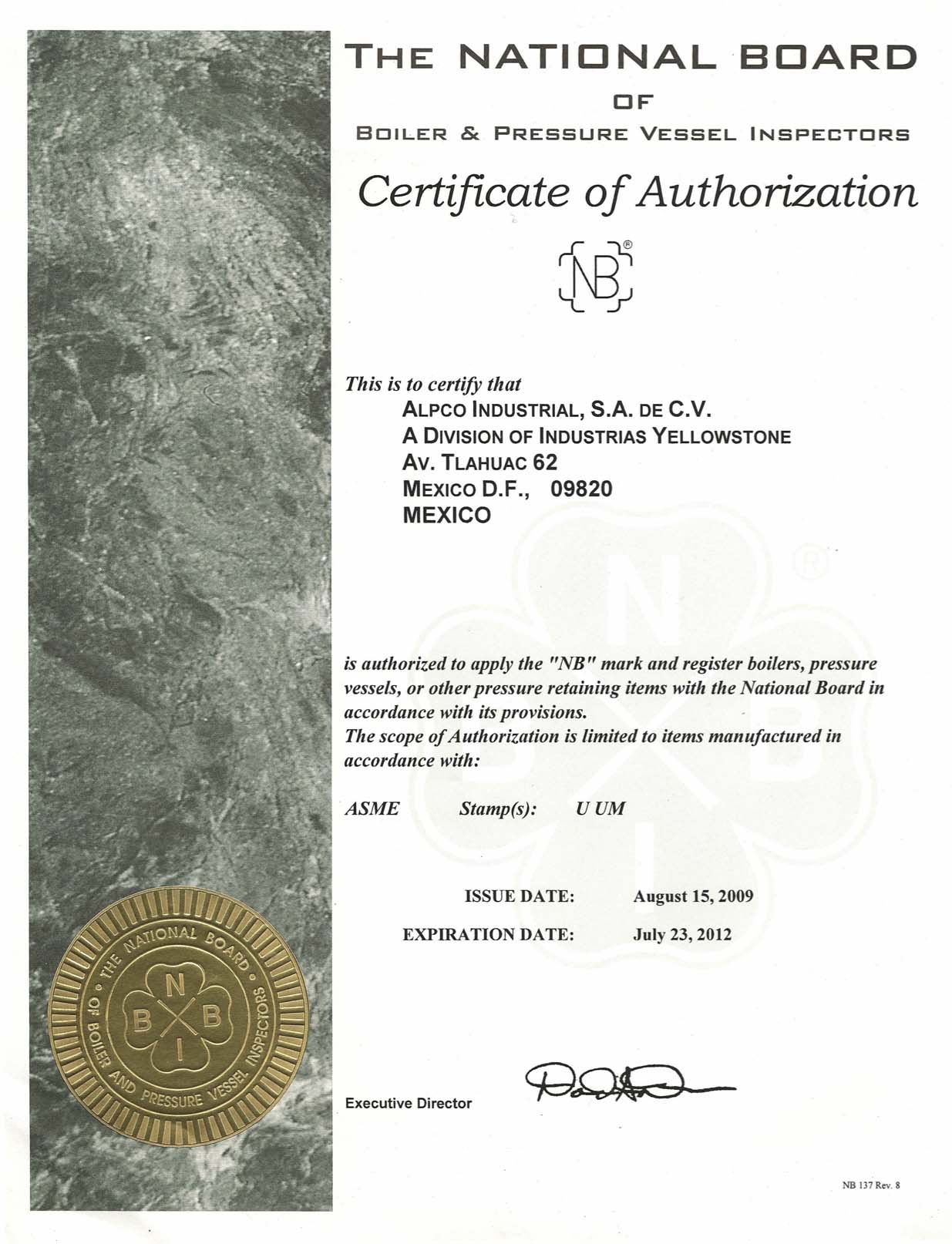

For The National Board of Boiler & Pressure Vessel Inspectors registration, we account with the "NB" Symbol. As well we account with the "R" Symbol to Repair or to Altair any previous Stamped Pressure Vessel.